Cutting-Edge Technology: The Optical Fibre Diameter Analyser and Its Impact on the Industry

Cutting-Edge Technology: The Optical Fibre Diameter Analyser and Its Impact on the Industry

Blog Article

Comprehending the Functionality of an Optical Fibre Diameter Analyser in Modern Production

The optical Fibre Diameter analyser functions as a crucial instrument in modern production, offering exact, non-contact measurements that are crucial for preserving stringent sector standards. By leveraging innovative laser technology, these analysers not just make sure marginal signal loss yet likewise improve the general performance of optical fibers. Additionally, their capacity for real-time data processing permits makers to promptly attend to any type of inconsistencies from specs, promoting a society of constant enhancement. Understanding the ins and outs of this modern technology raises concerns regarding its more comprehensive implications in manufacturing effectiveness and top quality control throughout various industries.

Importance of Optical Fibre Dimension

In modern-day production, the dimension of optical Fibre Diameter is essential for guaranteeing the efficiency and reliability of Fibre optic systems. Exact Diameter dimension straight affects optical performance, as variants can lead to raised signal loss, minimized transmission capacity, and decreased overall effectiveness. The optical buildings, including light transmission and signal stability, are very conscious the Fibre's Diameter, requiring accurate control throughout production.

Furthermore, standardization in Fibre Diameter is essential for compatibility and interoperability within varied telecommunications networks. As these networks increase internationally, maintaining harmony in Fibre characteristics advertises seamless assimilation throughout different components and systems. In addition, adhering to sector requirements concerning Diameter resistances is important for suppliers to satisfy regulatory needs and client assumptions.

Purchasing sophisticated measurement innovations not only improves making effectiveness yet also sustains quality control procedures, enabling makers to recognize problems early in manufacturing. This proactive technique reduces waste and ensures that the last items meet rigid efficiency standards. The value of optical Fibre dimension can not be overstated, as it serves as a foundation for top notch, reliable Fibre optic systems, which are indispensable to modern communication infrastructure.

Exactly How Diameter Analysers Work

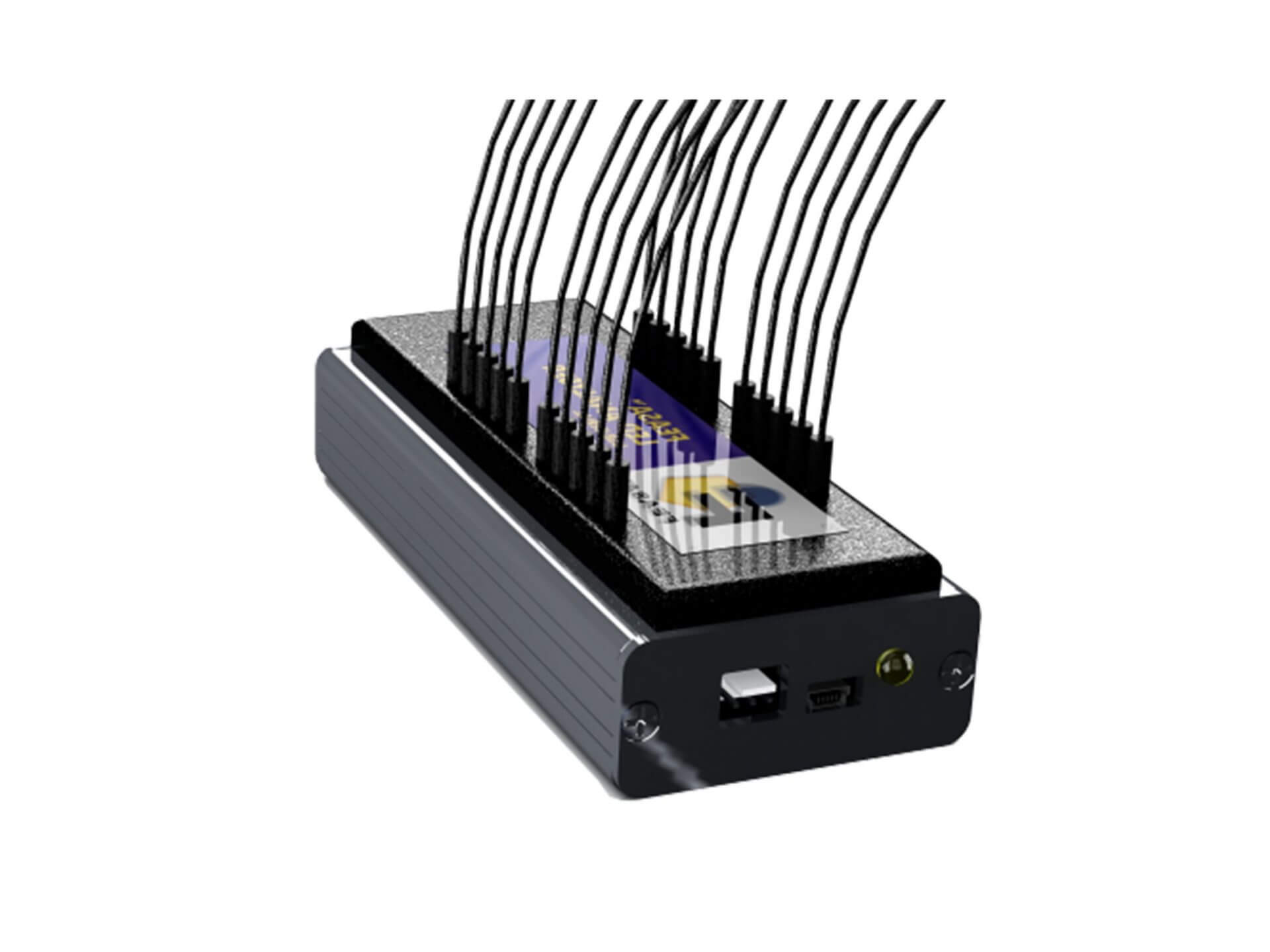

The core operation relies upon the principle of light spreading and reflection. As the laser beam strikes the Fibre, variations in Diameter reason adjustments in the light's intensity and wavelength (optical fibre diameter analyser). This information is processed in real-time using innovative algorithms that translate the optical signals right into exact Diameter dimensions

In addition, many Diameter analysers are geared up with multiple dimension points along the Fibre, enabling for a comprehensive analysis of Diameter consistency. This is crucial in making certain that the optical fibres fulfill rigid industry requirements. The entire procedure is automated, allowing high-speed dimensions and minimizing human error. The implementation of such modern technology considerably boosts high quality control in production, ensuring that optical fibers are created to specific specifications for optimum performance in their desired applications.

Secret Features to Think About

When choosing an optical Fibre Diameter analyser, numerous essential attributes warrant careful consideration to make sure optimum efficiency and reliability. First, dimension precision is extremely important; the analyser should offer specific Diameter analyses, typically in micrometers, to meet strict production specifications. In addition, a vast dimension variety improves convenience, accommodating various Fibre kinds and densities.

One more important attribute is the analyser's rate. Fast measurement capabilities allow for raised throughput, necessary in high-volume manufacturing atmospheres. Real-time information handling and comments abilities allow instant adjustments, boosting high quality control.

Interface and software program compatibility are likewise significant factors to consider. A straightforward user interface enhances operation, while robust software program support facilitates information Discover More evaluation and assimilation with existing manufacturing systems. The ability to export information in various layouts can enhance reporting and conformity efforts.

In addition, toughness and maintenance needs need to be assessed. An analyser created from top notch materials will withstand the rigours of a manufacturing setting, while ease of upkeep ensures durability and reduces downtime. Think about the level of technical assistance and training given by the producer, as this can dramatically impact the effective use of the analyser in manufacturing settings.

Benefits in Production Performance

Enhancing manufacturing effectiveness rests on the combination of innovative technologies, such as optical Fibre Diameter analysers. These instruments play a critical duty in guaranteeing that optical fibers satisfy rigorous quality standards, which is vital for optimum efficiency in various applications - optical fibre diameter analyser. By offering real-time measurements of Fibre Diameter, suppliers can swiftly identify and rectify discrepancies from specified resistances, therefore reducing waste and reducing the risk of defective products

Additionally, the very early detection of potential problems results in reduced downtime and maintenance costs, thereby enhancing resource appropriation. Ultimately, the performance gets realized with the use of optical Fibre Diameter analysers add to a much more affordable manufacturing setting, making certain that business can deliver high-quality products while keeping cost-effectiveness and responsiveness to market demands.

Applications Across Industries

The convenience of optical Fibre Diameter analysers prolongs past manufacturing performance, finding applications across numerous industries that depend on optical Fibre technology. In telecommunications, these analysers are official site crucial for making sure the optimum performance of Fibre optic cords, straight impacting data transmission rates and network integrity. By properly measuring Fibre diameters, drivers can decrease signal loss and enhance overall communication high quality.

The clinical sector additionally benefits considerably from these gadgets, specifically in the development of endoscopic tools and laser therapies. Accurate Diameter measurements are necessary for developing reliable optical fibers that are used in minimally invasive procedures, improving patient results with improved imaging and treatment abilities.

In aerospace, the analysers play an important duty in the manufacturing of light-weight, high-strength products, where Fibre optics are integrated into structural components for monitoring and diagnostics. Additionally, the automotive industry employs these tools to make certain the honesty of Fibre optic sensing units that improve security and performance features in vehicles.

Verdict

Finally, the optical Fibre Diameter analyser is essential for modern production, making sure exact measurements that support industry criteria. Its sophisticated laser innovation and real-time data handling capacities improve quality control and functional performance. By automating the measurement process, suppliers can quickly discover deviations, therefore decreasing signal loss and production downtime. The varied applications throughout various sectors highlight the analyser's significance in promoting continual enhancement and data-driven decision-making within the manufacturing field (optical fibre diameter analyser).

In modern-day manufacturing, the dimension of optical Fibre Diameter is critical for guaranteeing the efficiency and reliability of Fibre optic systems. The relevance of optical Fibre measurement can not be overemphasized, as it serves as a foundation for high-grade, reputable Fibre optic systems, which are integral to contemporary interaction infrastructure.

Diameter analysers utilize innovative optical technologies to precisely gauge the Diameter of optical visit fibres.Furthermore, lots of Diameter analysers are equipped with several dimension factors along the Fibre, allowing for a detailed assessment of Diameter consistency.The flexibility of optical Fibre Diameter analysers expands past manufacturing efficiency, discovering applications throughout numerous sectors that rely on optical Fibre modern technology.

Report this page